-

-

March

2022

APG Manufacturing - What Can We Make For You?

- manufacturing

- industrial glass

- sight glass

- gaskets

- vulcanizing

- couplings

APG (formerly American Packing & Gasket) is a fabricator, manufacturer, and an expert distributor of custom sealing, industrial couplings, and plastic products. Roughly half of our Houston-based, 85,000 square feet, facility is dedicated manufacturing space filled with dozens of specialized machinery and equipment to ensure quality and consistency in our manufacturing processes.

History of APG Manufacturing

APG is a leading manufacturer and distributor of fluid sealing and conveyance products which support markets and industries globally. We began as a small fabrication shop in the Houston metropolitan area in 1943. During this time, World War II was in full stride. Many of our employees and suppliers joined the war effort leaving APG with little product to sell. This led to the company to diversify its product line and branch off into various industries. APG’s manufacturing capabilities originated with hand-cutting gaskets, packing materials, and glass products.

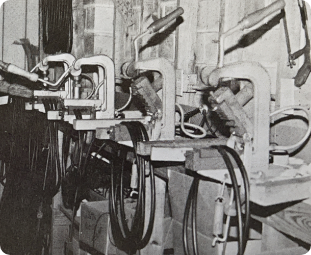

Vulcanizing 1982

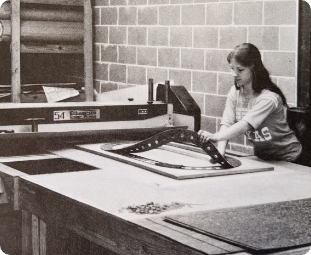

Cutting Gaskets 1984

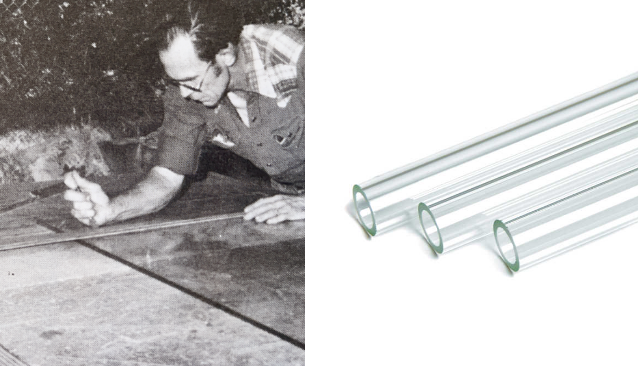

Cutting Glass 1977

Cam & Groove Couplings 1983

Manufacturing Value-Added Services

3D Prototyping

Utilize our CAD department to draw your part in a 3D workspace and let us materialize your part by 3D printing, ensuring sizes, tolerances, and overall design is exactly what you need.

Reproduction Capabilities

We have the capacity to design, manufacture, or reproduce any safety plastics products. Want more information? Contact us!

Custom Fabricated Gaskets

Utilize our CAD department, CAM systems, and extensive library of materials to create your custom gasket today.

Private Labeling

Want to customize your parts? No problem! We have the capacity to print and engrave directly on your industrial coupling parts as well as create custom molds to cast your logo directly on the item.

Custom Bagging

We have a bagging department dedicated to private labeled bags for our distributors. Custom quantities, parts, and labels are the start of the value chain we can provide.

Custom Die Creation

APG can create a die specifically for your part for high-volume runs or we can utilize our CAM systems for quick, low-volume turnarounds.

Custom Weld Fabrication

Need a highly specific part? Let us help. APG has large-scale manufacturing capabilities, a dedicated CAD department, and a network of partners to ensure we can turn around your custom part quickly and correctly.

Specialized Fabrication

Need a non-standard length glass? We have various machines and techniques to cut to your exact specifications.

Custom Plastics

APG is an expert manufacturer and distributor of custom plastic, eye, and face protection products. Our plastics division has produced products for many industries including dental, medical, mining, blast and surface prep, safety, and various others.

We use specialized abrasive blast techniques to produce volume runs of your finished product, which lowers production costs and meets delivery requirements. We use a variety of dies to ensure the best quality product is produced. If your product requires a specialty die, our skilled craftsmen will make one in-house or find it through our partners.

APG Plastics stocks a variety of sheet materials readily available for production. These materials include Acetate, Aluminum, HDPE, PC Polycarbonate, PET Polyester, PETG, and much more.

Our plastics division can make abrasive blasting replacement lenses, blast cabinet underlayment, respirator cover lenses, replacement safety visors, POP merchandising products, and much more. Talk to an expert today about how we can help you with plastics.

Vulcanized O-Rings

We have a fully dedicated team with decades of o-ring knowledge and experience readily available to vulcanize any custom O-Ring when you need it the most. We service a variety of industries such as oil & gas, petroleum, energy, semiconductor, and many more.

Vulcanized O-Rings are made from cut cord stock with both ends fused together by a super strong adhesive. These O-Rings are custom made with any dimension you need them to be. Our cords can be customized by the level of cuts such as a butt cut or bevel cut.

APG stocks over 300 different cord varieties with different combinations of material, durometer, cross-section, and shape. We have various materials in stock and are ready to be vulcanized into custom-sized rings. Materials such as Aflas , Buna N , Fluoroelastomer , Silicone , and more.

Industrial Glass

APG offers a complete line of industrial sight glass, gauge glass, and flat glass for any piping or tank wall application. Sight glass is important in a variety of applications as it allows the user to see the level of liquids or gases which are traveling through a critical point of your pipeline design.

Finding the right size of industrial glass can be a challenge, which is why APG can cut glass to any size or shape needed for your specific application. With our specialized machinery, cutting glass is met with precision and quality. We inspect each piece of glass to ensure there are no chips or cracks that formed during the cutting process.

APG stocks a variety of industrial glass such as redline tubular, heavy wall tubular, flat glass, and many chemical and high-pressure glasses. Learn more about industrial glass here.

Custom Gaskets

In need of a quick sealing solution? APG’s nearly 8 decades of gasket sealing experience is the perfect place to go. APG has hundreds of material styles to choose from to ensure every industry and application is covered.

We know not all seals are the same, which is why we offer custom gasket fitting solutions. With our specialized machinery, we can create any custom gasket out of any material needed for your specific application. Already have a CAD file? Send it to us and we will load and cut in a matter of minutes. Have a sample and need a digitized version? Utilize our CAD department to create your sealing solution.

Shop APG Manufacturing

Why shop at multiple businesses when you can get everything at one place? APG offers a variety of products and services to enhance your customer journey! Since 1943 we have been providing our clients with the high-quality products they need, as well as assistance in choosing the specific product and material that will work best for their application. Shop our products now, and if you have questions please don’t hesitate to contact us. We look forward to exceeding your expectations in both quality and service.

9 Most Common Types of Gaskets

If you have ever shopped for a gasket, you know that they certainly are not one size fits all. There are different materials, sizes, and even different types of gaskets. An understanding of the different types of gaskets...

The O-Ring Vulcanization Process

The vulcanization process consists of using cord material, adhesive, heat, and pressure to combine the two ends together to create a custom O-Ring in a matter of minutes. To get a glimpse of our process, watch our short video...

Stay Connected!

Get the latest updates on products, new knowledge base posts, and everything APG!